20

+

Countries Served

500

+

Projects Completed

50

+

Expert Teams

1000

+

Happy Customers

ABOUT US

FUTUR-ENG was founded in 2023 by two passionate Italian people who dedicated their careers to creating the homes of the future. It’s the result of a perfect symbiosis between an engineer and a project developer. However, it all started with a technology that was made in Italy.

FUTUR-ENG is a EPS-panel based modular building system made up of two electro-welded steel wire meshes, linked with each other by connectors, sandwiching a polystyrene foam slab suitably shaped hat contributes to distribute perfect heat insulation and sound proofing.

It is a versatile system, with a remarkable design flexibility and a complete capacity of integration to other building systems.

FUTUR-ENG is an innovative seismic-resistant and insulating building system. The easiness of assembling and handling and the extreme lightness and flexibility of the panels permit to design and produce any type of building, even in hard operational conditions, in areas at high risk of earthquakes or in severe weather conditions.

With our FUTUR-ENG system you can build a better future.

WHAT WE DO

Human beings are constantly changing their habitats with the aim of making it suitable for their demands; hence, persistently adopting a different building system closer to their current building needs.

The history of humankind also includes the evolution of production; therefore, it can be explained through the history and development of the construction industry. For centuries, human beings have used countless building systems to satisfy their primal needs.

With a rapidly changing industry where jurisdictions and environmental pollution have an increasing influence on how we build our homes, we as FUTUR-ENG feel responsible to be part of a change within that specific market. FUTUR-ENG strives to build more affordable, less polluting and more cost-effective homes for its people.

We want to create an opportunity for families and developers who are located in Belgium, The Netherlands and Luxembourg to build safe homes in an incredibly short amount of time, providing a high living comfort and having the added benefit of being energy efficient.

We know, it sounds incredible. That’s because it is.

Our Technology

A complete range of Panels, for every part of your Home.

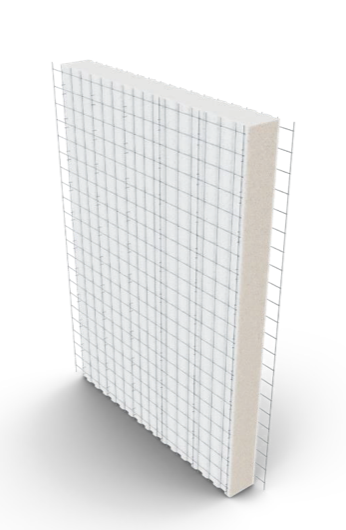

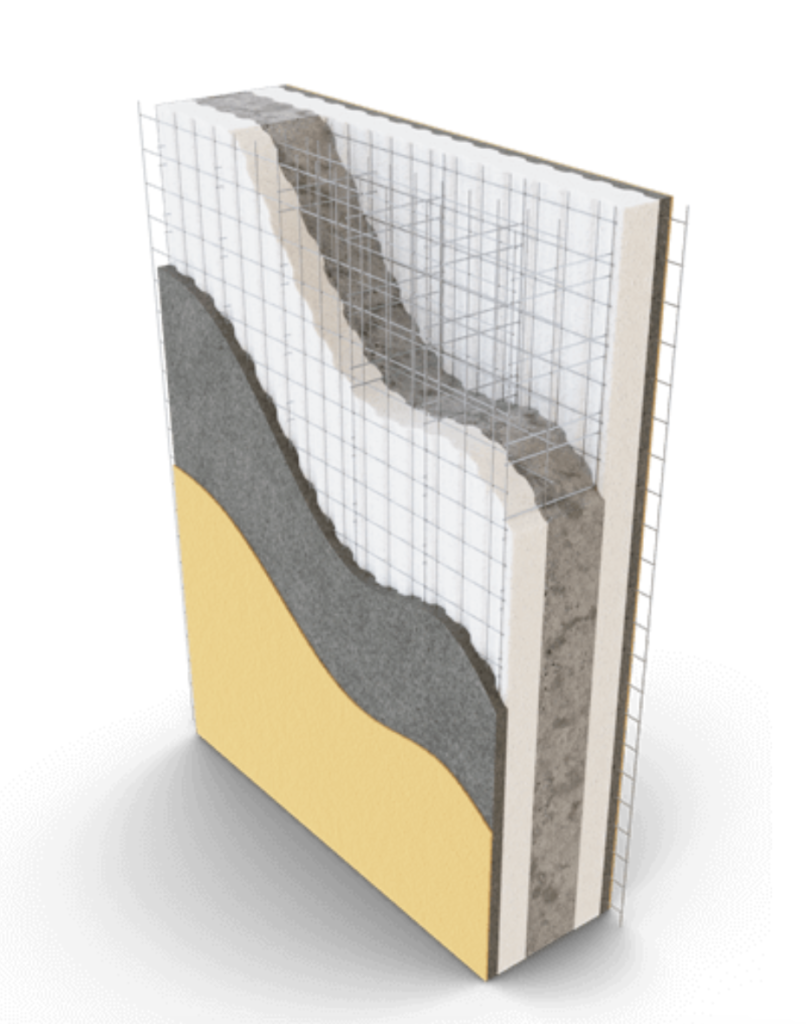

The Single EPS-Panel

The single panel is made up of expanded polystyrene, modular, enclosed in a double- galvanized steel wire mesh linked by connectors, to be finished with two layers of concrete.

Used as a supporting structure, for buildings up to four floors, with application of structural plaster on both sides. Perfect for the partitions and claddings in new or refurbished buildings; as a claddings and partitions in large-sized industrial and commercial buildings; as insulating frameworks for roofing and moderate spam floors.

Ideal for walls, partitions, cladding floors and roofs.

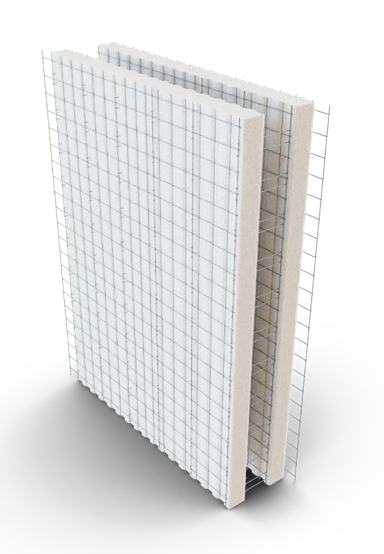

The Double EPS-Panel

The insulating double panel is ideal for reinforces concrete walls such as load-bearing and retaining ones.

The double panel is made up of two basic panels, shaped as required and joined together by double horizontal connectors which create a hollow core which is then filled with concrete of strength to meet the projects needed.

A layer of plaster is then applied to the panel on the outer surfaces.

Ideal for load-bearing walls and ground.

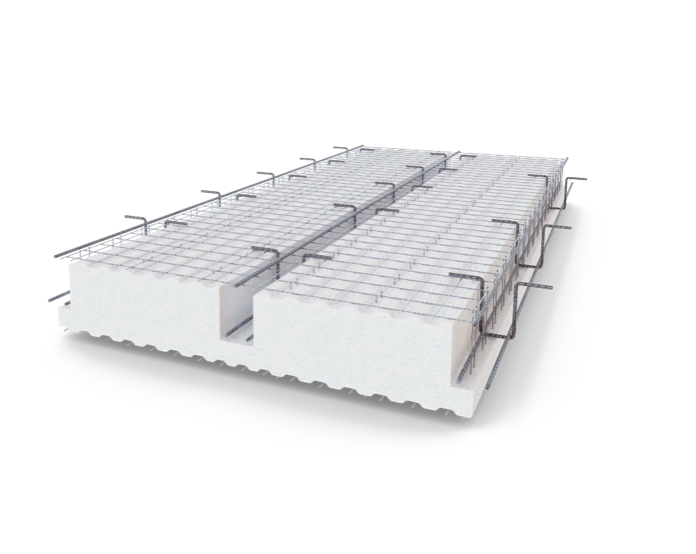

The Floor&Roof EPS-Panel

The floor and roof panel is used for creating floors and roofs with reinforces beams, with considerable advantages in terms of lightness, insulation and assembly speed.

It is composed of a molded sheet in expanded polystyrene, floors and roofing of buildings with the supplementary steel additions in special joists and subsequent casting of cement mix.

Ideal for floors and roofs with reinforces concrete beam.

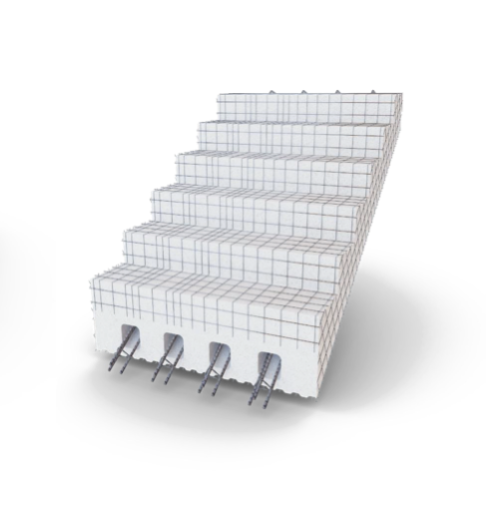

The Stair EPS-Panel

The stair panel consists of an expanded polystyrene block, shaped according to the design requirements and sandwiched between two steel wire meshes.

Once this panel is properly reinforces and completely casted in the appropriate spaces, it is ideal to build stair that can be superficially finishes with traditional plaster, tiles or any other type of finishing materials.

The stair panel is characterized by its quick and easy installation, combined with a distinct lightness and structural resistance.

The Landing EPS-Panel

Panel used to build landings, floors and bi-directionally reinforces plates. It gives continuous insulation to the intrados of the panel.

The landing panel is ideal for landings, floors and bidirectional armed plates.

+ Pre-reinforced sandwich panel with galvanized steel cage

+ Polystyrene slab for thermal insulation

+ Shotcrete on each side for structural resistance

+ Monolithic building shell

+ External surfaces supports any type of finishing

The FUTUR-ENG building panels, an in-depth look:

OUR SOLUTIONS

And did we mention that we have solutions for each type of construction?

Let’s start building the homes of the future, together.

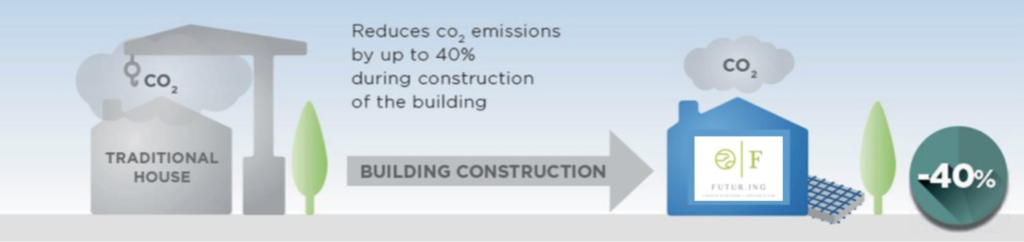

Green culture to build the future.

Buildings consume enormous quantities of energy. Their heating and cooling systems alone are already responsible for the greatest part of waste that one home consumes.

Energy efficiency therefore is the answer to reducing the rising energy costs and dioxide carbon emissions.

Building homes with the FUTUR-ENG EPS panels reduces CO2 emissions by up to 40% during the construction process of the building.

This then results in a lifetime reduction of 65% of the home-owners CO2 emissions during the use of the building.

THE FUTUR-ENG MANUFACTURING PROCESS

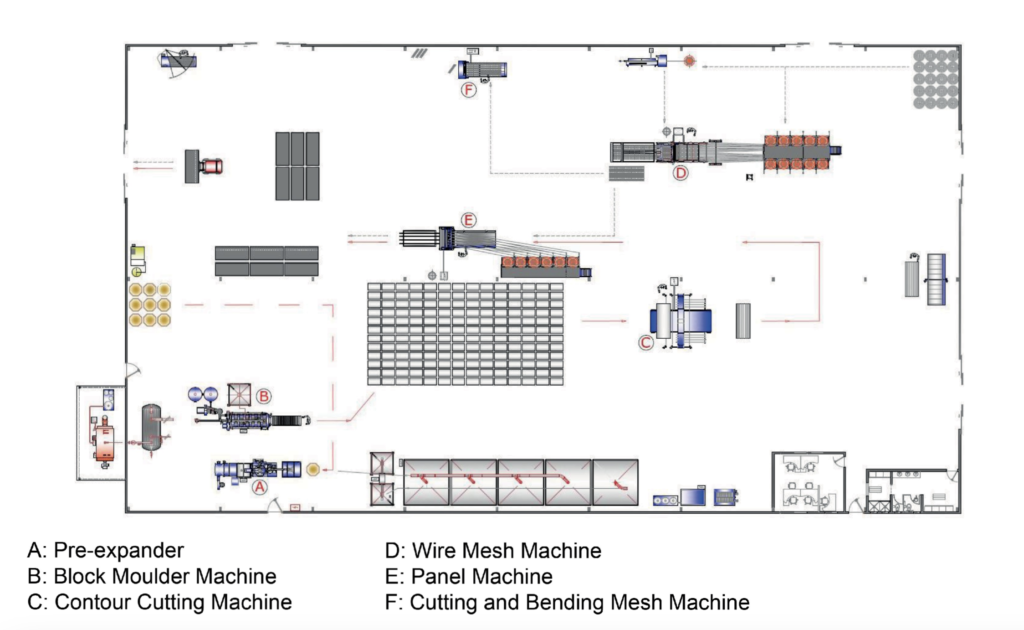

The FUTUR-ENG Fabric Plant

THE BEST OF FLEXIBILITY AND PRECISION

A unique plant consisting of the most sophisticated welding technique, great production efficiency and maximum safety standards for the production of every type of panel in the FUTUR-ENG range.

INTEGRATED SOLUTIONS

THE TECHNOPLANT MACHINE

The Technoplant Machine almost completely eliminates any human interaction, ensuring high productivity and quality levels.

The whole line is managed by and industrial PC on which four control points are positioned along the line to allow the operator to control the process from anywhere in the plant.

Oh, and have we talked about the benefits yet?

Benefits for the builder

COST-EFFECTIVENESS

+ Up to 20-30% less costs to build with the

+ FUTUR-ENG system in comparison to a traditional building system

RAPID INSTALLATION

+ It takes up to 50% less time to build with the

+ FUTUR-ENG system in comparison to a tradition building system

VERSATILITY

+ Applicable to all kinds of constructions

LIGHTNESS, EASE TO TRANSPORT & HANDLING

+ Reduced transportation of materials for one project

SUSTAINABILITY & ENERGY EFFICIENCY

+ Up to 40% less CO2 emissions during the building process

+ Up to 65% less CO2 emissions for home- owners

PANELCAD® SOFTWARE

M2 PanelCad®, the latest evolution in the field of integrated design for the building industry, is an innovative and easy to use software to offer designers high-quality solutions:

+ Ideal to design both simple and complex buildings of any shape with the use of FUTUR-ENG Panels

+ Can be fully integrated with most of standard designs, as it uses compatible, transportable and editable formats such as DWG, DXF, DGN.

DESIGN

+ Import building projects

+ Select the types of panels and wire mesh

+ Design roofs and ceilings of any shape and angle

+ Create openings for doors and windows

+ Provide customers with a 3D execution impact simulation

ESTIMATE

+ Amount and price of the various panels and additional reinforcement wire meshes required for the project

+ Amount of cement needed to spray concrete onto the entire structure

+ Additional steel for wall joints, floor, stairs and landing

+ Manpower required for panel installation and concrete spraying

ASSEMBLE

+ Create a nesting plan (joint) showing the grouping of out-of-standard size panels to optimize (reduce to the minimum) the scrapes of panels

+ Prepare an assembly plan with the configuration details of the panels for each area of the building

+ Print the assembly plan to be used on-site

Contacts

Are You Looking to Working with us?

Contatc us!

Fill out the form below with all the data and questions you want to ask us, one of our employees will answer you within 24 hours.

We accept communications in: ENG, IT, ES .